Firewall Insulation Revisited

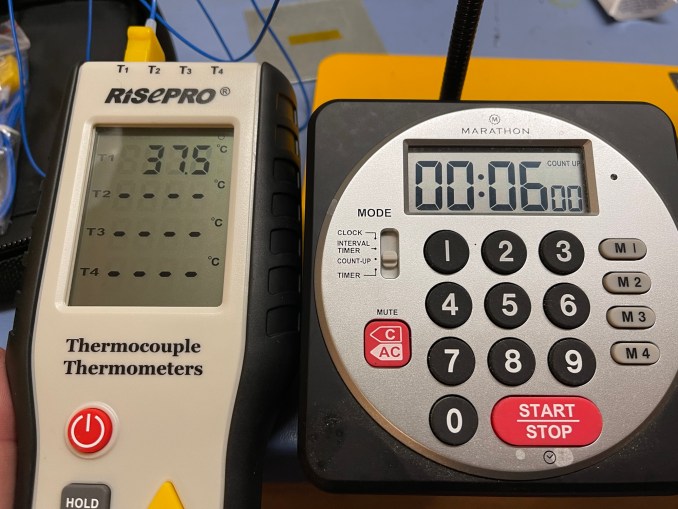

I was about to spray adhesive for the Thermotec insulation I chose for the firewall, when suddenly I questioned how well it would insulate the cabin from engine heat (and noise). So, I performed a short test using 4” square test pieces of 26 ga. galvanized steel: one bare (control sample), a second with Thermotec glued to the face, and a third with the kit-supplied FIREX30 foam attached to the face. I attached a thermocouple to the back side of each steel plate, then hit the face of each coupon with a small jet of hot air from an SMD rework station set to 160°C. The nozzle of the heat gun was set 2” away from the steel plate. Each of the samples reached a steady state temperature after about 6 minutes. Starting from room temp of about 25°, here’s what I observed for each sample:

- Bare steel (no insulation): 67.7°C

- Thermotec: 57.3°

- FIREX30: 37.5°

This test showed FIREX30 coupon performed better than the other two test articles, so I expect it will do a better job of resisting heat and noise from entering into the cabin. Although this material seemed to melt more quickly when exposed to a flame as shown in this informal testing on YouTube, the result was still acceptable.

Given its superior insulation performance, I decided that I’m back to using the kit-supplied FIREX30 firewall insulation. I’m a little surprised that the Thermotec heat barrier didn’t perform better, but perhaps it performs well in other applications.